Manufacturing Plant

| Base | : | Dongguan City, Guangdong Province in China |

| Area | : | 14,350 sq. m |

| Staff | : | Around 160 workers (Direct and indirect employees) |

Production Facilities

We have R&D, Tooling, Wire Processing, Plastic Injection, Engineering and Quality Control Departments, as well as an in-house testing laboratory. Our production is strictly operating in accordance with ISO 9001 quality management systems.

Our production lines include:

- Fully Automatic Wire Cutting and Terminal Crimping

- Semi-Automatic for Cable Cutting and Terminal Crimping

- Plastic Injection

- Assembly Processing

- Soldering Processing

Facilities for Plastic Injection

Our R&D Team can provide design and manufacture of injection molds. We also have the capability to make independent plastic parts according to customer’s unique design and requirements. Plastic Injection is available with various materials such as PBT, Nylon, ABS and PC for different applications.

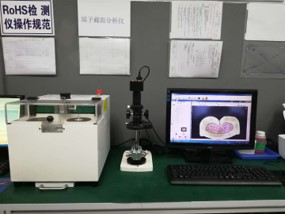

Testing Facilities

With full suite of industry-standard testing equipment, our products could be ensured as durability, reliability and safety.

- Vision Measuring Machine

- 3D Microscope

- Wire Sequence Detector

- Terminal Tension Tester

- Bending Tester

- Micro-ohmmeter

- Aging Tester

- Salt Spray Tester

- RoHS Measuring Instrument

- Terminal Crimp Cross Section Analyzer